10. Potential asteroid fragmentation technology

|

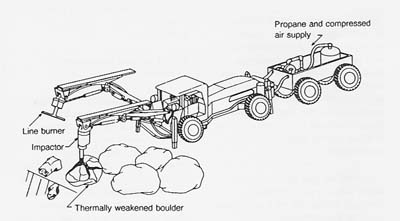

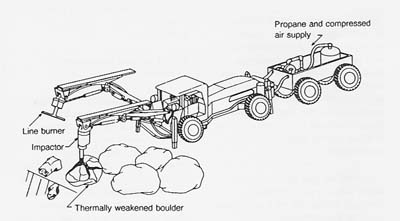

Thermomechanical Boulder Breaker

A mobile thermomechanical boulder breaker could fragment rock by first weakening

it by applying heat (in this concept by means of a burner) and then hitting it with a mechanical impactor.

From Thiruma/ai, Demou, and Fischer 1975, quoted by Maurer 1980, p. 653.

|

Technology for fragmenting rock particles has been researched and developed over

many decades. Conventional fragmentation is primarily mechanical. Its effectiveness on a virtually gravity-free

asteroid will depend in part on the degree to which the mechanical fragmentation system depends on gravity. We

can conceptualize mechanical fragmentation systems that are independent of gravity; i.e., those that work by

splitting or pinching. Also available are a variety of explosive, electrical, chemical, and thermal disintegration

methods. These methods will impose different logistical requirements, depending on what supplies they need and on

how operations are carried out. For example, the efficiency of several fragmentation methods would increase if the

fragmentation took place in drill holes. But drilling holes in asteroids will pose unusual problems (see topic 6).

It may be desirable to distinguish between two classes of fragmentation problems, those where

a single fragment (or a small number of fragments) is to be removed or reduced to certain dimensions, and those

where a large number of particles are to be reduced in size. The latter class of applications is discussed under

topic 15, crushing and grinding. The choice of technology most readily applicable to removal or controlled-size

reduction of a single large block might well benefit from an evaluation of quarrying practice for building stone.

Advanced rock disintegration techniques, some of which should have direct applicability to space operations, are

summarized by Maurer (1980).

|

11. Automation, operator proficiency, and excavation efficiency

Eliminating the need for human operators would significantly enhance the economic attractiveness of

nonterrestrial mining. Few attempts have been made at developing fully automated mining excavation cycles; i.e.,

operations without human intervention. The economic incentives for doing so on Earth are marginal, at best.

Fully automating the mechanical excavation and loading of broken rock is likely to result in

drastic productivity losses. It is well established that the productivity of virtually all excavation and loading

equipment is highly sensitive to the expertise of the operator. Human judgment and fast response to seemingly minor

aspects of rock loading operations are significant production and safety factors. Of particular concern in this

context is that misjudgment by an operator can result in serious, even disastrous, consequences, such as cables

breaking and machines overturning. Control engineering will have to preclude such occurrences as well as assure

a reasonable production level.

The importance of human judgment in excavation technologies suggests a number of avenues for

research aimed at identifying candidates for automation and nonterrestrial application. Questions that can be

raised include the following: Will the implementation of automatic operation be most difficult for equipment

that is most sensitive to operator handling? Should automation be preferentially applied to excavation technologies

that are robust or insensitive to operator errors? What tradeoffs are acceptable between automatic control and productivity?

To allow automation, operations should be as simple as possible. This fact, explicitly recognized

in the space program (e.g., Firschein et al. 1986, p. 103), unquestionably underlies the mining industry's reluctance

even to attempt to automate most excavation methods. The few notable exceptions (Iongwall mining, tunnel boring) for

which automation is being investigated are already fully mechanized (involve minimal human intervention during normal

operations). These exceptions tend to be high-production systems. They are prone to frequent breakdown and require

preventive maintenance. Maintenance is recognized as a major difficulty in implementing automation (e.g., Firschein

et al. 1986, p. 355); it will require major developments in artificial intelligence software and robotics. The need

for human reasoning capability is again apparent.

12. The influence of gravity on slusher mining

Gertsch identifies slusher mining as one of the more promising

lunar mining methods. The performance of a slusher on the lunar surface (or

in underground operations on the Moon) will be affected by the low gravity.

The lighter weight of the scraper (bucket) on the Moon may lower the loading

efficiency of the slusher bucket, because the weight influences the vertical

penetrating force into the material to be loaded. Conversely, the lighter weight

lunar material may flow more easily up into the bucket. It is conceivable that

artificial weighting down of the bucket, or a reconfiguration of the cable force

system, might be required in order to assure adequate penetration into the lunar

soil and to avoid riding of the (empty or partially filled) bucket over the

material to be loaded. Conversely, friction, abrasive wear, and power requirements

during both inhaul and outhaul may be significantly reduced by the low gravity.

The reduced effective weight of the bucket, which is likely to have a detrimental

impact on the efficiency of the all-important bucket-loading phase, might also

adversely affect the performance of the bucket as it is hauled in to the unloading

point. Assuming a relatively rough and bumpy ride during inhaul, the bucket

may not retain its full load. An analysis might suggest a reduction in hauling

speed, but this might also affect production adversely. It is possible that bucket redesign

and cable reconfiguration might compensate at least partially for the reduced

effective bucket weight.

Given the interest by this group in the application of slusher mining to the

lunar program, it may be appropriate to outline in some detail steps that could

be taken to reduce the need for speculation about the performance of such systems

on the Moon.

Obtaining a clear understanding of the mechanics of bucket loading

would be a desirable step. This step could be initiated with a comprehensive

literature survey. It is unlikely that much fundamental information is available

about slusher bucket mechanics, but considerable analysis has been made of the

mechanics of similar excavation elements, such as dragline buckets, bulldozer

blades, front-end loader buckets, and scrapers. Integrating this knowledge in

a framework emphasizing the mechanical differences between terrestrial operating

conditions and lunar operating conditions would go a long way towards identifying

potential problems. Such an integrating effort should be made by a group with

a clear understanding of the fundamental mechanics of the machine (bucket) and

material (broken rock). At a minimum, meetings should be organized with experienced

bucket designers from various manufacturers. In order to obtain maximum contributions

from such personnel, it may be preferable to formally contract for their technical

services. Equally important would be information exchanges with operators; e.g.,

by means of visits to mines.

On the basis of the initial analyses, it should be possible to make preliminary

estimates of the influence of gravity on bucket loading performance. This information

could in turn form the basis for designing experiments (for example, experiments

using centrifuges) to verify the analyses. Similarly, it may be possible to

instrument buckets and their cables and chains in order to obtain a better understanding

of the distribution of forces during loading. An appropriate iterative sequence

of bucket analyses, experiments, and design modifications should provide a considerably

improved understanding of bucket mechanics, ultimately leading to adequate bucket

designs for drastically different operating conditions.

While I have emphasized slusher bucket development, I should point out that

any studies of this type, aimed at an improved understanding of the mechanics

of loading broken rock, will be beneficial for eventual redesign of other systems

that might be considered for nonterrestrial loading operations. These would

include hydraulic excavators, electric shovels, front-end loaders, bulldozers,

scrapers, draglines, and clamshells.

Next

Table of Contents