13. Wear-resistant materials for space mining applications

Equipment maintenance is one of the most expensive and time- consuming (in terms of production delay) aspects of mining operations. The most critical maintenance aspect of all excavation equipment is the wear rate of excavation elements (e.g., buckets, their teeth, drag cables). Similarly, components of equipment for haulage and for crushing and grinding, which are subject to repeated impact and abrasion, may require frequent resurfacing or replacement. Replacement schedules and parts requirements need to be estimated in order to develop realistic life-cycle cost estimates. If wear parts had to be provided from Earth and if conventional replacement schedules needed to be maintained, the transportation requirements of nonterrestrial mining would be considerable.

It is virtually certain that the thermal environment, with its extremes of cold and hot, will significantly increase the wear on some components. Less certain, but nevertheless possible, is that increased friction due to the vacuum environment (Karafiath and Nowatzki 1978, p. 130) may contribute to accelerated frictional wear.

Wear components, especially excavation components, tend to be made of very heavy steelalloys. Assuming that in parallel with lunar mining will proceed in situ manufacturing [including production of metals (Ehricke 1983)], it may be worthwhile to consider tradeoffs between transporting high-quality wear parts and producing lower quality wear parts locally.

14. Remote sensing of rock excavation characteristics

The potential of remote sensing to characterize the lunar surface for equipment mobility has been mentioned by Karafiath and Nowatzki (1978, p. 492). The significant impact vehicle traction may have on mining operations has been discussed under topic 8. With respect to mining itself, whether excavating hard rock or scooping up and loading soil, remote sensing will be equally important in determining strength, particle shape and size, interparticle friction, and other excavation parameters. While a final assessment of excavation feasibility will almost certainly require direct physical access, it is clear that remote sensing should be used to the greatest possible extent in determining excavation characteristics of possible mining sites. The importance of remote sensing obviously is well established in the space program, but we should note that interpretation in terms of minability may pose some unusual requirements.

15. Particle size reduction technology for applications in space

Mechanical reduction of particle size is usually not considered part of the mining cycle. It immediately follows the mining cycle, however, and optimizing the total sequence works better than optimizing the mining and milling operations separately.

Crushing is typically the first step in reducing the size of the mined rock. Most crushing systems depend on gravity feed and flow (Wills 1985, ch. 6). Gravity directly affects fragmentation in some systems (Motz 1978). Its influence may not be fully appreciated in others, as it has never been considered a significant variable. The forces acting on particles during crushing in a low-gravity environment will differ markedly from the forces operating in conventional situations. It appears likely that crusher geometries

(e.g., jaws, cones, throats) might need to be modified for operations in an environment with drastically reduced gravity or that throughput rates might require considerable adjustment. Increased frictional force components may be beneficial in some crushing systems (Wills 1985, p. 169) but could be detrimental in others.

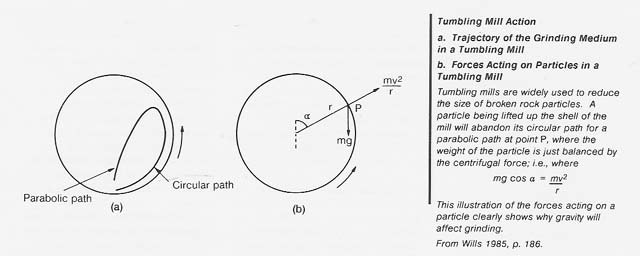

Grinding particles, either dry or submerged in liquids (Austin, Klimpel, and Luchie 1984; Wills 1985, ch. 7), is usually the final particle size reduction step. It is not obvious how significant the effects on grinding of a low-gravity,. high-vacuum environment may be. In the most widely used tumbling mills, particle size reduction is accomplished primarily by impact. Gravity forces enter very explicitly into the design of these tumbling mills (Wills 1985, p. 186). Hence, an analysis of gravitational effects should be straightforward. Such an analysis would be worthwhile because it addresses the most energy-consuming aspect, by far, of size reduction operations. Wet grinding, almost always preferred, clearly would pose problems in logistics (delivering or producing the liquid) and in containing and recovering the liquid.

>Particle size classification is an important control procedure applied throughout the milling sequence. Most sizing methods depend on gravity to some extent. The final fine particle size classification most commonly is accomplished by differential settling in liquids, a method that would pose the same problems for space mining as would wet grinding.

The milling operations discussed here deserve consideration along with mining methods in order to optimize the entire sequence. Such an integrated optimization may shift the degree of fragmentation desired from the mining portion of the operation. The desired fragmentation may affect excavation, loading, and hauling.

Conclusions

The applicability of conventional mining technology to space mining can currently be evaluated only on the basis of judgment and speculation. I have presented a list of research topics that correspond to information needs which must be answered in order to put such evaluations on a firmer basis. In many areas, relatively simple analyses of the mechanics of the system and of the impacts on it of gravity, atmosphere, and temperature could add quantitative understanding of the operation of terrestrial mining technologies in. nonterrestrial environments. Iterative interactions between space engineers and scientists on the one hand, mining engineers on the other, and the integrating researchers performing the analyses should assure that the investigations stay correctly focused. Such investigations could be of considerable benefit to the mining industry, and this terrestrial technology transfer aspect deserves specific recognitiontion.

I have given examples of conventional mining technologies which might be adapted to nonterrestrial applications, as well as examples of technologies that have not found practical applications on Earth. I propose that two approaches be pursued in parallel: one starting from available technology and identifying needed adaptations; the second starting from likely ultimate objectives and developing solutions unencumbered by conventional practice and thinking.