|

Muck Pile

This is an example of a good muck pile, well-fragmented

and largely remaining in one heap. Loading would be much more time consuming

if the rock were widely dispersed, as it might be by conventional blasting

in a low-gravity environment, without air resistance. The loading machine

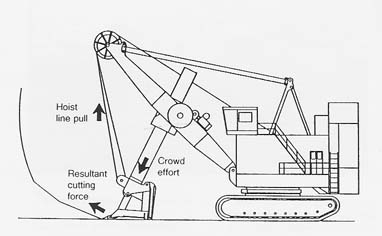

must have sufficient traction (created by both friction and weight) to

be able to push the loading bucket into the muck pile.

|

Lunar mining may involve the removal of various types of ground, ranging from

massive solid rock to loose, granular soils. This possibility suggests the need to investigate a range of

material- removal technologies. It may be desirable, at this early investigation stage, to distinguish between

the fundamental mechanics underlying the technologies and the technologies themselves. Both will be affected by

operations on the Moon, but in different ways.

a. Hard rock excavation mechanics

In earthbound mining, hard rock is removed primarily by explosive excavation. Lunar blast design is likely

to require significant changes from conventional blasting. An obvious consideration will be the need to

control the broken rock pile. It is usually assumed that gravity plays no role in actual rock breakage by

conventional blasting, but it plays a significant role in displacement of the broken rock (and thus dominates

the shape of the muck pile). Low gravity could result in extremely wide scattering of rock fragments, even more

so in the absence of air resistance, and hence lead to exceedingly inefficient loading operations. An interesting

challenge may be posed by the need to adjust blasting patterns from the traditional ones to those designed to

minimize scatter in a low-gravity and high-vacuum environment.

It is possible that vacuum might affect blasting performance,

although it may not be a significant factor in low-permeability rock,

at least at greater depths. The breakage induced by blasting is usually

attributed in part to seismic effects and in part to gas pressure effects.

Presumably gas pressure effects could attenuate much faster in a space

environment than on Earth. This could affect fragmentation and almost

certainly would affect heave and throw; i.e., rock movement.

Potential impacts of low gravity on mechanical excavation have been discussed

under topic 1. Drastically different excavation technologies are summarized

by Maurer (1980), and they deserve intense scrutiny for lunar applications.

b. Soft ground excavation mechanics

Mechanical excavation of loose, granular material on the lunar surface is likely to be facilitated

by the lower gravity in terms of actually lifting the material, although this improvement may be partially

offset by increased friction between particles. It is likely that the most significant detrimental effect

will be on the forces that can be delivered by the equipment. Reduced equipment weight will reduce breakout

forces and sliding stability. It is quite possible that even a simple force analysis of excavation systems

will shed considerable light on lunar soil loading requirements and potential problems. Gertsch has suggested

that we add mass to lunar equipment by building into it large volumes to be filled with lunar rocks. However,

as he notes, the added mass would add to the problem of inertia in mobile equipment.

|