The degree to which nonterrestrial mining operations will be run automatically or under remote control (i.e., the extent to which people will need to be present at or near the mining operation) will have a major economic and logistical impact on the type of operation that can be implemented. Remote control over very short distances (that is, with an operator not more than tens of meters from the equipment) has become readily available for mine face operations (continuous mining of coal; longwall mining; drilling; train, truck, and loader movements; etc.). There has been some success in running underground operations from a great distance [see, for example, the article in Coal Age, vol. 92 (1987), no. 8, p. 61], admittedly on an experimental basis.

Even a cursory review of recent mining literature reveals the industry's considerable interest in the subjects of remotely controlled and automated mining (e.g., Atkinson, Waller, and Denby 1987; Hopkins 1987; Scales 1987; Stricklin 1987). It appears virtually certain that considerable progress will be made in these areas in the near future. However, we must acknowledge that highly optimistic announcements about forthcoming mine automation have been made repeatedly, and for at least two decades.

Given the potential importance of automated and remotely controlled mining for nonterrestrial operations, I think it appropriate to recommend an intensive effort to evaluate the current state of the art of such technologies, with emphasis on operations in hostile environments. Mining experience has shown that the environment poses severe problems, especially with regard to transducer performance (see, for example, Atkinson, Waller, and Denby 1987 and Stricklin 1987). I propose that an interactive investigation of such problems with authorities in other fields would be beneficial in identifying possible solutions. Specifically relevant may be remotely controlled equipment for handling nuclear materials, especially for reactor cleanup operations (Kring, Herndon, and Meacham 1987), as well as sensors, transducers, and transmitters developed for the space program (Stuart 1983; Wagner-Bartak, Matthews, and Hill 1983; Firschein et al. 1986). I think it likely that an integration of already existing knowledge may result in readily available improvements to the control systems typically used in mining.

Similarly, it may well be that cost considerations have so severely affected mining systems design that their reliability is unacceptable for space operations. Economic tradeoffs in nonterrestrial mining are almost certain to be different from those in earthbound mining. Hence, it may well be that the reservations and concerns about control engineering which have been generated by mining experience may not be appropriate to space designs. An obvious first step in resolving these uncertainties is simply to assemble a group of experts with relevant backgrounds and have them discuss the problems.

3. Environmental effects on lunar surface mining

Environmental factors such as temperature, air pressure, dust, and visibility have a significant impact on mining operations and equipment. Of most immediate concern is the difference in temperature and atmosphere for nonterrestrial mining as compared to conventional earthbound mining. This difference has significant implications. The cold of the 2- week night on the atmosphereless Moon virtually eliminates the possibility of nighttime operations with conventional equipment because of the problem of material brittleness. And the heat of the 2- week lunar day, un shielded by an atmosphere, will impose demanding cooling requirements. A team of space equipment designers and mine equipment designers should be able to identify mechanical and electrical problems and potential solutions, as well as the redesign needs implied by these solutions. Daytime lunar surface operations, particularly rock loading, could be severely affected by perception problems induced by the bright sunlight and constantly changing shadows (discussed by Firschein et al. 1986, p. 112).

4. The applicability of conventional mining methods and equipment to lunar mining

When one considers the applicability of Earth technology to lunar mining, one can focus rapidly on a likely lunar project and retrofit an available mining method to meet the characteristics of this particular project. However, I propose that program benefits might derive from a comprehensive analysis, at a preliminary scoping level, of the applicability of conventional earthbound mining methods and technology to lur\ar operations. Such an analysis could proceed from a comprehensive matrix, listing mining methods along one axis and lunar features (such as logistics, gravity, vacuum, temperature, perception problems) likely to affect mining along the other axis.

To each mining method, one can assign weights for the various differences between terrestrial and lunar operations. Initially the weighting could be done on the basis of expert judgment. But as soon as possible the weighting should be based on a numerical analysis. For simple mining methods, the weights could be based on the mechanics of the system. For complex methods, the weighting may require a comprehensive numerical simulation of an entire sequence of operations. This technique would allow a formal assignment of level of difficulty likely to be encountered in applying the terrestrial technology to the lunar situation.

An effort of this type should be iterative. The initial list may include technology that is entirely inappropriate or exceedingly difficult to modify or implement. In parallel with such iterations, one might also expect a progressive refinement in the information needs about the most likely operational conditions.

5. Underground construction methods for lunar application

a. Underground Mining

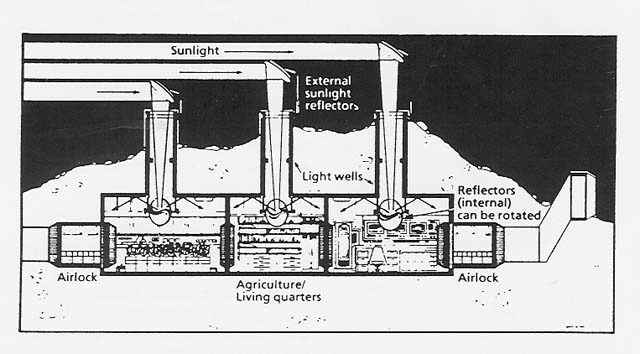

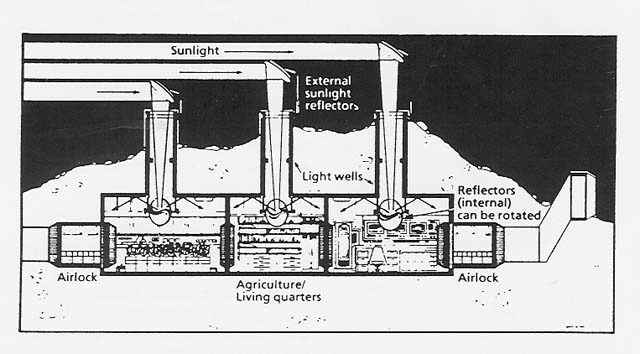

Although the baseline lunar mine was conceived to be a strip-mining operation, there may be locations where the regolith is so thick that it could be mined by some undercutting scheme. Excavations could be driven below the material to be mined. and the material could be drawn into the excavations for milling. The light wells in this illustration could correspond to draw points for bringing material directly underground. and the agriculture/living quarters could correspond to the scene of all subsequent mining operations, which would thus be shielded from the hazards of the lunar surface environment.

As pointed out under topic 3, the environment will impose severe limitations on surface operations on the Moon. It therefore appears fully warranted to investigate the feasibility of moving mining operations underground. Lunar scientists can probably provide information on the subsurface lunar temperatures, and this information may encourage the investigation of going underground.

|

Operating underground on the Moon raises a number of intriguing questions. Conventional support systems such as concrete, steel, and shotcrete are likely to have an even less favorable weight-to- performance ratio than on Earth. Hence, the economics of their application need to be investigated in detail. As I briefly outline under topic 7, the preclusion of conventional support systems would not necessarily exclude underground construction in weak or disintegrated ground, but it would put a premium on developing reinforcement methods, integrated with the construction cycle, which minimize weight requirements. Given that the most frequently encountered and most severe problems for earthbound underground construction and mining arise from unexpected conditions (that is, sudden changes in ground quality), it is virtually certain that underground lunar construction should be preceded by markedly better site investigation and characterization than is the norm on Earth. Underground construction on the Moon should have some significant advantages when compared to earthbound practice. Most underground construction problems are associated with water, because of excessive pressure, excessive flow, or both. Indeed, a standard if somewhat overstated saying among engineers holds that "a dry tunnel is an easy tunnel." The absence of water will facilitate underground construction on the Moon. Moreover, the certainty of not encountering water will eliminate the need to plan for the contingency. The increased friction (more intimate physico-chemical bonding) in vacuum (Karafiath and Nowatzki 1978, p. 130) should assist in stabilizing underground excavations. It may also make excavation somewhat more difficult, but excavation per se usually is a relatively minor cost factor in underground mining. The low gravity will increase the weight-carrying capacity of equipment and reduce the energy requirements of muck haulage and particularly hoisting. Light levels, and hence visibility, may be easier to control underground than on the lunar surface. Underground construction on the Moon will differ from underground construction on Earth in a number of important aspects. Its potential advantages over surface construction appear to warrant a comprehensive assessment of its merits. Such an assessment should address all aspects that affect life-cycle costing. |

b. Tunneling for Lunar Habitats

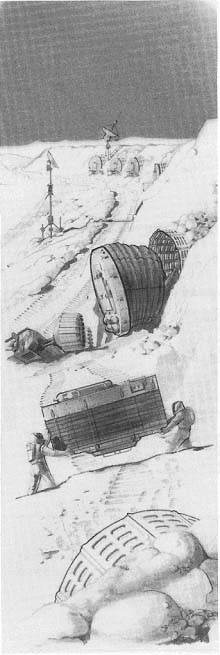

Perhaps the tunneling techniques developed for mining could be used to construct lunar habitats. The two astronauts in this illustration provided by Encyclopaedia Britannica seem to be having no difficulty carrying a capacious pressurizable module for a tunnel. In gravity only 1/6 that of the Earth, the required weight-carrying strength of equipment as well as people could be reduced to 1/6 that required on Earth.