Different types of rock drilling are likely to be required on the Moon. Certainly core drilling will be desirable, if not essential, for collecting samples for rock characterization tests. But alternative, much less expensive hole-drilling techniques (in which the material from the hole is not kept intact) may be considered for such purposes as anchoring structures, explosive fragmentation, or even sample collection.

All conventional rock drilling methods, including diamond coring, rotary drilling of soft rocks, and percussion drilling of hard rocks will be affected by differences between lunar and terrestrial operating conditions. Most obvious are differences in gravitational pull, atmospheric pressure, and thermal conditions.

The very low gravitational forces on the Moon are likely to require a thrust system designed to assure adequate drilling progress. This could be a passive (weighting) system or an active Uacking) system. Regardless of which approach is taken, it seems very likely that drilling equipment will require significant modifications in order to provide the necessary thrust.

The lack of atmosphere on the Moon will create complications in providing and maintaining drilling fluids. In conventional practice such fluids are needed, in considerable quantities, in order to remove cuttings from the hole and to cool the drill bit. And on the dry and highly fractured surface of the Moon, these fluids would be easily lost. Cooling of the bit, as well as of the drilling motor, may be further complicated by the thermal environment on the Moon. This will certainly be a complication during daytime operations on the surface.

In sum, fundamental aspects of rock drilling are affected significantly. This impact will be reflected in needed changes to drilling equipment and operations. A first step in the investigation will be to determine as narrowly as possible the expected conditions under which drilling will have to be performed. This determination will in turn allow an identification of the basic parameters to be used in evaluating changes in fundamental drilling mechanics and hydraulics. Finally, such changes will lead to equipment modifications, if not to totally new drilling designs.

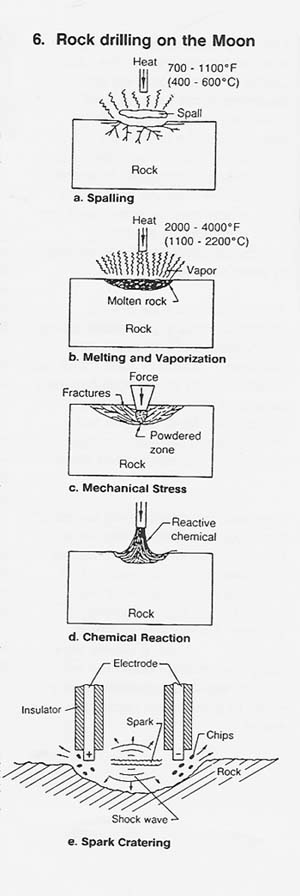

While this discussion has centered nearly exclusively on conventional drilling technology, I should point out that extensive investigations have been made of numerous, radically different drilling technologies (e.g., Maurer 1980). A variety of reasons, including high conversion costs, institutional inertia, and the fact that most novel drilling methods require large amounts of energy, have so far prevented the widespread implementation of such alternative drilling methods. The novel drilling and rock excavation method that has found most widespread application-water jet excavation- is inappropriate for space applications. For reasons similar to those discussed under the next topic (rock melting), tradeoffs will need to be made between energy use (high for novel technology, low for conventional drilling) and delivery weight (low for novel technology, high for conventional drilling).