Ballistic transport of the glassy slag waste from the smelting of ilmenite will be more of a problem. For regolith that is 10 percent by weight ilmenite, the slag waste produced will be on the order of 80 percent of the ilmenite or 3200 metric tons per year. Slag waste will contain much larger and more angular particles, which are less suited to ballistic transport. If the iron is extracted, the slag waste drops to 40 percent or 1600 metric tons per year. These figures are based on 100-percent separation efficiencies.

Costs and Time Line

Terrestrial three-drum slushers are relatively inexpensive yet rugged. A terrestrial slusher with the production profile outlined above costs on the order of $100 000. While the lunarized version proposed here adds several features to the terrestrial model, the redesign, addition of control circuits, and testing could be accomplished for less than $10 million. The same design simplicity that lowers the cost of operation will help keep down the research and development cost of the slusher.

After a mining site has been selected and a lunar base has been built, placing the slusher in operation is simple and can be accomplished in about 6 months. Setup time would include final operational testing on the Moon.

Design, manufacture, and testing of a fully operational machine is a modest, well-defined task.

-------------

The following is one of a series of 5-minute radio programs. Entitled The Engines of Our Ingenuity, the series is written by mechanical engineer John H. Uenhard and presented by the University of Houston's College of Engineering.

Ceredi's Pump

Now and then I run into a student who says, "I like engineering just fine; but why should I hafta take philosophy?" He fails to see that what we do is shaped by the way we think about things-that our technology and our philosophy bend to fit each other. Here's an example:

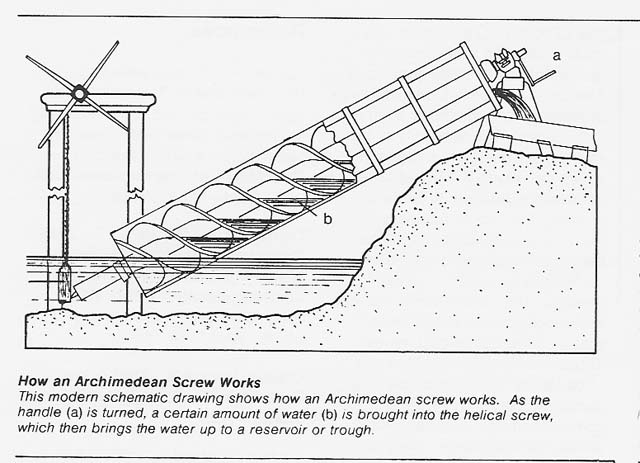

Archimedes invented a really clever pump in the third century B.C. It's been used all over the world, ever since. It looks like a tube coiled around a long axle. You tilt the axle and put its lower end in water. Then you turn it. The open end of the tube picks up water and, as the coil turns, water passes from one loop to the next until it comes out at the upper end.

It's a pretty subtle gadget-not the sort of thing you just stumble across. Archimedean pumps were widespread in the classical world, and Roman authors described them. . . . Well, they tried to. We've just seen that they aren't easy to describe.

Archimedes' pump didn't do so well during the High Middle Ages when European attitudes were strongly shaped by Aristotle's philosophy. Aristotle very clearly separated motion into two kinds-motion in a straight line and rotary motion. These pumps mixed the motions. They used rotation to move water upward along an axis. They were anti-Aristotelian, and they were hard to find during the Renaissance.

Ceredi's Pump (conciuded)

Now, in 1565, a Renaissance agricultural engineer named Giuseppe Ceredi patented an Archimedes pump. He systematically described the installation and use of batteries of these pumps for both irrigation and drainage. But we wonder how he could be given a patent for a known device.

When you compare Ceredi's dimensioned drawings, flow calculations, and economic analysis, with the almost unreadable Roman descriptions, you begin to see why. Ceredi might well have found the idea in the old literature; but he put flesh and blood on it. After Ceredi's work, these pumps were quickly accepted across Southern Europe. They were not, as one author puts it, .. something that would be created spontaneously by peasants" And they certainly weren't something that people would take up naturally In a world that didn't want to mix straight-line and rotary motion.

Ceredl had a right-brain ability to visualize. He had a left-brain ability to execute and organize detail. But he was also able to break the straitjacket of Anstotellan thinking. A few years later Galifeo took up full-scale combat with Aristotelian ideas of motion. And Ceredi's reinvention of Archimedes' pump was a harbinger of that philosophical revolution.

Conclusions

Any startup project in a new environment will have many unknowns. We do not even know all the questions, much less the answers. Mining ventures are very risky here on Earth and most of them fail. The space environment with its many unknowns adds greatly to the degree of difficulty. Keeping the project small, well defined, and simple will help ensure success.

Humans' experience working in space is very limited; our experience in nonterrestrial mining does not exist. Consequently, one significant but indirect benefit of the LOX-to-LEO project will be the experience gained in exploiting lunar materials. This experience will be the basis for later, more ambitious projects, either on the Moon or on other bodies.

Whatever lunar mining method is used, the slusher or something else, must be kept as simple as possible because simplicity means 1ower costs. The slusher is not particularly efficient or flexible, but it is simple and cheap.

The LOX-to-LEO project is very small compared to terrestrial operations, even small gravel pits. The small size allows consideration of nontraditional methods such as the slusher. The simplicity of the slusher has great advantages in a small operation. If a larger lunar operation is desired, consideration of other methods is mandatory. For example, machines such as the continuous miner should be particularly suitable to mining regolith. The continuous miner has wide application and has been proven in terrestrial coal mines. Traditional methods such as the truck-loader combination can also come into play. This mining combination has long been the workhorse for a wide variety of terrestrial mines.

More complex lunar mining methods may have a greater terrestrial transfer potential. A fully automated machine may find a' significant terres,trial market. If so, such methods could amortize their development costs by supplying a wider market than the Moon.

The slusher itself has unresolved problems, even for the small LOX-to-LEO project, Only a few of these problems have been mentioned here. To ensure success, any lunar mining method must solve these problems effectively. Problem definition fgr a lunar mine has only just begun.

References

Carrier, W. David.; Leslie G. Bromwell; and R. Torrence Martin. 1972. Strength and Compressibility ot Returned Lunar Soil. Proc. 3rd Lunar Science Cont., Suppl. 3, Geochimica et Cosmochimica Acta, 3223-3234. M.I.T. Press.

Carrier, W. D., III. 1979", Excavation Costs for Lunar

Materials. In Space Manufacturing III, Proc. 4th Princeton/AIM Conf., ed.

Jerry Grey and Christine Krop, 89-96. New York: AIM.

Church, Horace K. 1981. Excavation Handbook. New York: McGraw-Hili.

Gertsch, Richard E. 1983. A Method for Mining Lunar Soil. 10 Advances in the Astronautical Sciences 53 (Proc. Princeton Conf. Space Manufacturing 1983, ed. James D. Burke and April S. Whitt): 337-346. San Diego: American Astronautical Soc.

Ingersoll-Rand Company. 1939. Modern Methods for Scraper Mucking and Loading. Ingersoll- Rand Form 2412. 11 Broadway, New York, NY.

Williams, Richard J.; David S. McKay; David Giles; and Theodore E. Bunch. 1979. Mining and Beneficiation of Lunar Ores. In Space Resources and Space Settlements, ed. John Billingham, William Gilbreath, and Brian O'Leary, 275-288. NASA SP-428.