Asteroid Mining by Richard E. Gertsch

The earliest studies of asteroid mining (e.g., Johnson and Holbrow 1977) proposed retrieving a main belt asteroid. Because of the very long travel times to the main asteroid belt, attention has shifted (Billingham, Gilbreath, and O'Leary 1979, O'Leary 1983) to the asteroids whose orbits bring them fairly close to the Earth. In these schemes, the asteroid would be bagged and then processed 9-uring the return trip, with the asteroid itself providing the reaction mass to propel the mission homeward. A mission to one of these near-Earth asteroids would be shorter, involve less weight, and require a somewhat lower change in velocity (delta V). Since these asteroids apparently contain a wide range of potentially useful materials, our study group considered only them.

Asteroid Materials and Properties

The forces driving the consideration of asteroid mining are their varied materials and favorable retrieval delta V (see John S. lewis's paper in this volume). Combining information from spectral studies of asteroids and laboratory analyses of meteorites, investigators have postulated near-Earth bodies rich in volatiles (water, halogens, and organics) and metals (structural, precious, and strategic). While no asteroid prospect has yet been identified, the possibility of obtaining such materials for cislunar operations from a source requiring low delta V is exciting and should be pursued.

Furthermore, samples in the form of carbonaceous chondrites and similar classes of meteorites indicate that their parent asteroids may have favorable mechanical properties. Some of these materials break up easily at pressures as low as a few bars (105 N/m2) (see table 17 in John Lewis's paper). This breakup pressure is much less than that for most terrestrial materials. For example, some material can be crushed by hand. Although other asteroids may be fundamentally tougher, impacts may have broken up their surfaces into regolith (soil). Thus our study group came to believe that material from a near- Earth asteroid should be easily excavated and rather easily crushed by mechanical comminution equipment already developed for terrestrial applications.

Asteroid Mining

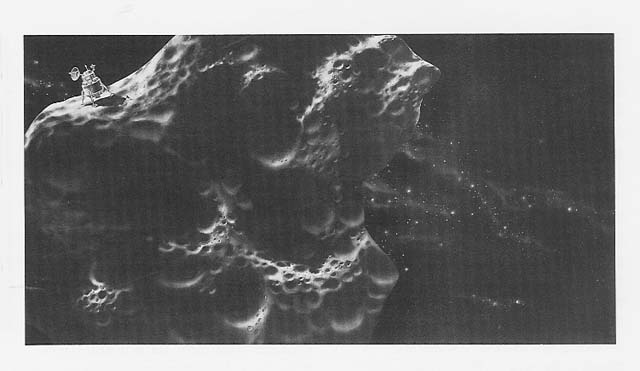

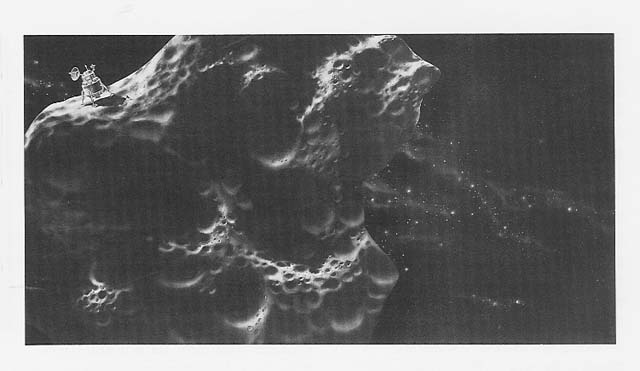

Asteroids have resource potential. notably the potential for providing water, which can be decomposed into hydrogen and oxygen for propellant use. Asteroids may have rough cratered surfaces, as illustrated in this painting. If they are water-rich, they are likely to be similar to carbonaceous chondritic meteorites. which are very black, with extremely low albedos. Such asteroids may be rather soft and friable and thus easily mined.

Artist: Dennis Davidson

Asteroid Mission Selection

While the latest studies of retrieval and processing methods indicate that the project is feasible, the selection and the execution of an asteroid return mission are still fraught with problems. These problems stem from two basic causes: no candidate asteroid has been identified and the long trip time imposes severe limits 0.0 the mission. The results seem attainable but only with much more work.

Identifying an Asteroid Prospect

From the perspective of the terrestrial mining industry, lack of a specific asteroid candidate or prospect means that no project exists. Mining projects are so sensitive to actual site characteristics that an asteroid mining mission cannot be justified on circumstantial evidence. This is particularly true of an unmanned mission, where everything must work properly the first time and without human intervention.

Confidence that a feasible asteroid prospect exists in the near-Earth environment is based on statistical analysis. Given the known distribution of near-Earth asteroids and studies of their compositions, it seems probable that a candidate can be located, if enough resources are applied to the search effort (see Michael J. Gaffey's paper in this volume). Physical properties of prospective candidates - mineral grades, mineral variability, specific mechanical characteristics of the asteroidal material, and orbital characteristics-must be determined before significant development of an asteroid mission proceeds.

Nevertheless, a basic understanding of what an asteroid mission might entail is readily at hand. Using the possible orbits, mineral compositions, and mechanical properties of the near- Earth asteroids. one can construct a range of potential missions. The feasibility of such a mission can be established and comparison can be made to a lunar mission, such as the LOX-to-LEO project. Sensitivity analysis of asteroid mission profiles and comparisons to lunar projects can begin almost immediately. Criteria can be developed that will guide selection of candidate asteroid bodies. The expected range of flight characteristics, combinations of ore grades, ore types, mechanical properties, flight durations, and transportation costs can be determined and the range compared to that of a lunar project.

Long Mission Duration

Long travel times to near-Earth asteroids pose significant economic and operational problems. Physical sampling of the candidate body would take as long as the mining mission, so the flow of risk- reducing information is slow. The sampling mission would take a year or more, there may be a long wait for the next mission window, and then the mining mission would take another year or more. Thus, the lead time could be very long. When the mining mission finally flies, an expensive mining plant would have been in orbit a year or more before use. This unproductive time significantly raises the mission's cost. The round-trip time of 2 years or more lowers the rate of return on investment in plant and equipment.

Mission feasibility depends on the right choice of three basic types of missions: a long-duration manned mission, an automatic or teleoperated mission, or a mission in which the manned portion accepts high L\ V and the equipment arrives by slow Hohmann transfer orbit. Determining the proper choice will require extensive research and development, which, of course, increases mission cost. Each type has its advantages and disadvantages, both during the mission and in later technology transfer. The basic tradeoff question-manned or automatic/teleoperated - has yet to be answered.

Manned Versus Automated Missions

Manned Missions

While the problems and expense of a manned mission are obvious- long-term exposure to zero gravity, exposure to dangerous solar radiation, designing controlled ecological life support systems, and man-rating a deep space vehicle Gust for starters)-our study group, with its terrestrial mining perspective, suspects that an asteroid mining mission will require human miners. The reason is our skepticism about the ability to economically automate such a mission. Not only has progress in terrestrial mine automation been slow, but a)so the prospect of applying such technology to an environment with so many unknowns is daunting.

Automated Missions

The benefits of automation are derived from economic considerations and not simply from eliminating people from the production loop. If automation decreases production costs, it should be used. This principle is important even in highly automated industries such as automobile manufacturing. Tasks that are repetitive and boring yet require precision are the best candidates for automation. In this realm, the experience of General Motors illuminates the point. GM's new, largely automated assembly plant has yet to reach production goals and has a myriad of problems. Increasing the production rate and maintaining the required quality while lowering or maintaining production costs justifies the increased capital cost of automation.

Some mines, particularly longwall coal mines, have successfully achieved partial automation of a relatively repetitive mining system. It was accomplished in small steps: One easily defined machine operation or task was automated while the rest of the operations remained manual. After debugging and redesign, the automated operation achieved the required degree of reliability. Then, another candidate for automation was selected and the process was repeated. Over several years, a reliable and integrated but not fully automated system may thus be painstakingly built. In general, terrestrial mine automation has been confined to remote sensing of mine parameters, such as ventilation and equipment status, and production monitoring.

Complete mine automation has been shown to have too great a capital cost to be effectively amortized over the production life of a mine. Furthermore, mining operations have a much greater number of degrees of freedom than does automobile manufacturing. Besides increasing capital (and R&D) costs, operations that are not exactly repetitive have more automation problems than do repetitive operations. Thus, mining costs are not lowered by automation as much as product manufacturing costs are. The fact that the harsh mining environment is much harder on equipment than is a closed plant environment only aggravates the problem.

This experience does not close the door on automatic/teleoperated asteroid missions. It does indicate caution when contemplating these missions. The automatic/ teleoperated asteroid mining equipment must work perfectly. Even small equipment failures cause the mission to fail. An expensive R&D effort is needed to ensure such perfection. As with the lunar case, the lessons learned in flying an automatic/teleoperated asteroid mission may find extensive terrestrial application, helping to amortize the large R&D costs.