Lunar Mining Operations

The baseline self-propelled slusher excavates a triangular area 50 meters in base and height. At a mining depth of 2 meters, approximately 9000 metric tons are excavated per setup. Approximately one setup per lunar day yields a yearly raw material production of 100 000 metric tons. Mining would cease during the night, as the extremely low temperatures would make operation difficult. But milling could continue, as the mill is more easily protected from the environment. Production figures are based on terrestrial experience; lunar gravity will allow increases without increasing machine size. It should be noted that production can readily be increased by manipulating several machine variables without significantly changing machine weight. Variables such as bucket size, span, reach, and motor power all affect production. No attempt was made to optimize these factors; instead the machine was oversized to show a very basic feasibility. Empirical optimization is required during design and prototype testing.

Although the normal mining pattern is a V, mobilizing the power/loader unit allows more flexible patterns (fig. 23). The mobile unit allows the machine to excavate more convenient rectangular areas rather than triangular ones.

Some weight savings could be gained by using a two-drum slusher. With one outhaul cable instead of two, the machine excavates a straight line rather than a triangle. The decrease in flexibility may not be worth the small weight savings, but the two-drum solution should be investigated. By moving the power/loader unit or the pulleys, the two-drum slusher can be made to excavate a rectangular area, but the moves slow the rate.

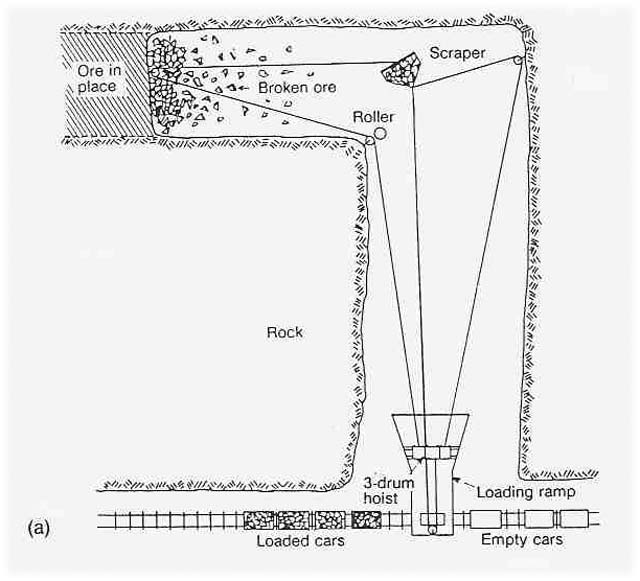

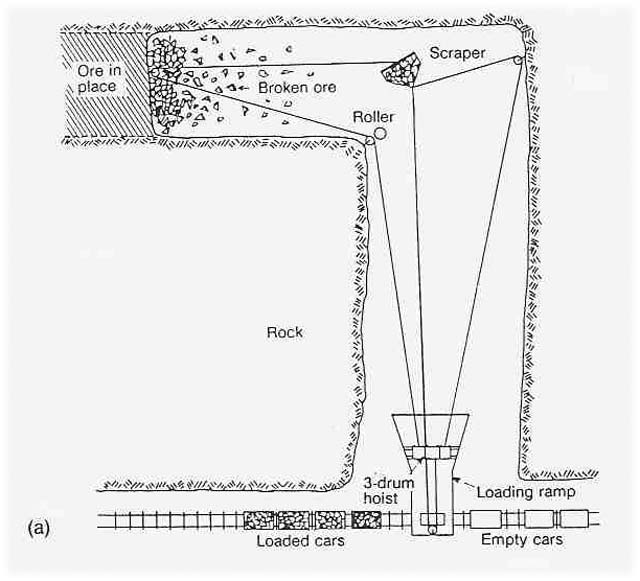

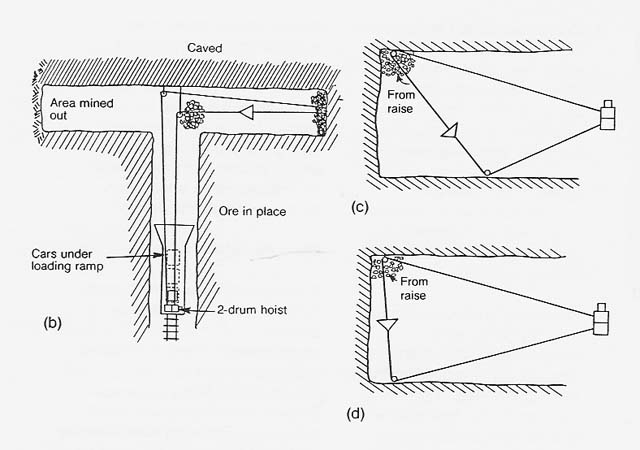

Figure 23

Various Slusher Mining Patterns

These underground slusher mining patterns demonstrate the slusher's flexibility in

mining different shaped areas.

Figure a shows a three-drum slusher scraping around a corner

Figure b shows a two-drum slusher scraping around a corner, but note that It takes two scraping operations.

Figures c and d show how a changing setup allows a two-drum slusher to mine outside its restricted narrow path.

Both the two- and three-drum slushers can mine a wide variety of areas: triangles, rectangles, right angles, etc.

However, each different setup requires downtime to reset the pulleys or the power/loader unit.

Taken from Modern Methods for Scraper Mucking and Loading by the Ingersoll-Rand Company, 1939.

Modular Components

Every opportunity should be taken to divide the slusher (and other equipment) into modular components. The modules should be as interchangeable and transportable as possible. Two general types of modules envisioned are large functional modules, such as mining units, material cruushers, and electrostatic separators, and small equipment modules, such as electric motors and power distribution panels.

Modularity increases flexibility and reduces downtime without adding equipment weight.

Accomplishing modularity is relatively easy in small-production mining facilities-: (By terrestrial standards, the lunar slusher operation is very small.)

Auxiliary Vehicle

A small, self-propelled auxiliary vehicle will probably be necessary, even with a mobile slusher or other mobile mining method. It will find use hauling broken components to the repair shop and replacement modules to their operating positions. as well as hauling people and materials back and forth. It should have a crane to aid in constructing habitats and repairing equipment. Adding a small conveyor to the vehicle would allow it to heap up Joose regolith for habitat shielding. This general-purpose vehicle will be smaller than the vehicle required to move a stationary slusher from site to site.

Shop Facilities

A pressurized repair shop would facilitate complex repairs by providing a shirt-sleeve environment. There is no good reason to rewind an electric motor in a vacuum. Since lunar dust is ubiquitous and insidious, some system for removing dust from the shop and its equipment must be provided. Equipment from the outside must be cleaned of dust before it enters the shop.

However, a shop would add significant launch weight unless it could be fabricated on the Moon. launch weight considerations dictate a careful mix of tools, equipment, and spare parts for the shop. The shop and repair activities are there to keep the mine operating while helping to keep transportation costs for tools and spare parts to a minimum.

In addition to tools and spare parts, the shop could eventually have a small adjacent foundry to cast pulleys, bearings, and other easily fabricated parts. The foundry will probably not be in the shop but outside in the vacuum. This plan assumes lunar metal production.

Fiberglass ropes of lunar origin to replace Earth-made cables are also candidates for early lunar manufacture, as glass is a byproduct of LOX production. Glass manufacturing methods were not considered here.

Mine Waste Disposal

Depending on required products and milling processes, some fraction of the mined material will be waste which must be removed from the production area. This fraction can be quite significant (e.g., terrestrial.. copper operations yield only 10 kg of product per metric ton of ore; thus, 1990 kg of that tonne is waste). The LOX-to- LEO project will generate two types of waste. Fines waste is the soil fraction rejected by electrostatic separation. Slag waste results from the smelting process. Production of liquid oxygen from regolith that is 10 percent ilmenite will generate mostly fines waste, on the order of 90 percent of the material mined or 36 000 metric tons per year. Providing a vehicle for waste disposal would add significant launch weight, and the waste disposal options must be studied.

Robert Waldron and David Carrier* have both proposed a ballistic transport mechanism that could be usable in lunar mining. It is well suited to removing fines waste. Using a simple mechanism such as an Archimedean screw (see box) or conveyor flights, it is possible to ballistically transport fines waste several hundred meters away from the production area. Their preliminary calculations indicate that the mechanism could be built at a reasonable weight. A ballistic transporter, along with a storage and feed bin, could be added as part of the mill module or as a separate module. The ballistic transporter could also be used to heap up material for habitat shielding.

*Personal communications.