The Lunar Environment and Machine Design Principles

The major reason for proposing the three-drum slusher is to illustrate problems to be expected in a lunar mining project.

Simplicity in Design and Operation

Compared to other mining machinery, the three-drum slusher is quite simple in design and operation. This simplicity yields several interrelated advantages.

Traction Independence

Mobile mining equipment depends on traction to generate sufficient loading forces on the blade or scraper. Most terrestrial mobile equipment loads near its traction limit. On the Moon, reduced gravity creates a less favorable inertia:traction ratio. Increases in traction are achieved by increases in mass, but increases in mass add inertia, which decreases control of a moving machine. To achieve the same traction as on the Earth, a mobile machine on the Moon would have to have six times as much mass. This greater mass would cause correspondingly higher inertial resistance to turning and slowing.

Slusher loading forces are supplied through the cable, thus almost eliminating traction problems. The scraper bucket will have to be more massive than on Earth, simply to cause the bucket to fill. To lower launch weight, the extra mass needed by the scraper bucket can be supplied by lunar rocks.

Since the slusher is a relatively low-production method, upscale lunar mining projects will eventually use mobile mining methods. It is necessary to address inertia- traction problems as early as possible. Further study may find that long-term considerations argue for using mobile equipment from the very beginning. As with the scraper bucket, the extra traction mass can. be supplied by lunar materials. Perhaps traction could be improved by new tread or track designs.

Mining Flexibility and Selectivity

The lunar slusher differs from the terrestrial slusher by one major design addition: the power unit is mobile rather than stationary. This allows the machine to set itself up and eliminates the need for an auxiliary vehicle. Most important, by adding a dozer blade, the machine can doze undesirable rocks from the pit. Such large rocks would impede mining operations if the power unit were stationary.

The mobile power unit makes the machine more selective. By allowing the power/loader unit to reposition, the slusher has some ability to separate different soils during the mining process or to go into the pit and mine a small area of interest.

Mining Tools for Selecting Particle Size and Breaking Regolith

The ability to change from a scraper to a rake allows the machine to select different size fractions. For example, if fines are required, the area can be raked on the outhaul. so that oversized rocks are moved to the far side of the pit. Then the rake can be exchanged for a scraper to mine the remaining fines. If larger sizes are desired, they can be raked in on the inhaul.

Other tools, such as rippers or plows, are used to break difficult ground. Lower levels of lunar regolith appear to have a high degree of compaction (Carrier 1972) and must be broken before mining can take place. Although it is the usual terrestrial practice, chemical explosive blasting appears to be prohibited by the high cost to transport the explosives to the Moon. The ripper or plow greatly increases machine working depth. It has already been established that the slusher, unlike mobile loading equipment, is independent of traction. This traction independence allows the slusher to break difficult ground while still maintaining a light weight. More lunar geotechnical engineering data is needed, however, and the design of the ripper is unknown. The ripper probably needs an attached weight to force it into the regolith. A plow may be better than a ripper, as its shape helps pull it into the soil, making it less gravity dependent.

High-Tech Low-Tech Mix

The redesigned slusher exemplifies a design philosophy favored by the study group. The basic machine design is nearly 100 years old and has a track record proven in many applications. See figure 22. In a lunar application, the basic operating principles remain unchanged but the machine becomes lighter, stronger, and more efficient by liberal use of advances in materials science. Light, high-strength alloys or graphite fiber might replace steel in the machine's structural and wear members. Graphite fibers might replace steel cables. Other opportunities to improve the slusher should present themselves. Thus, the lunar machine is a low-tech off-the-shelf design with high-tech execution.

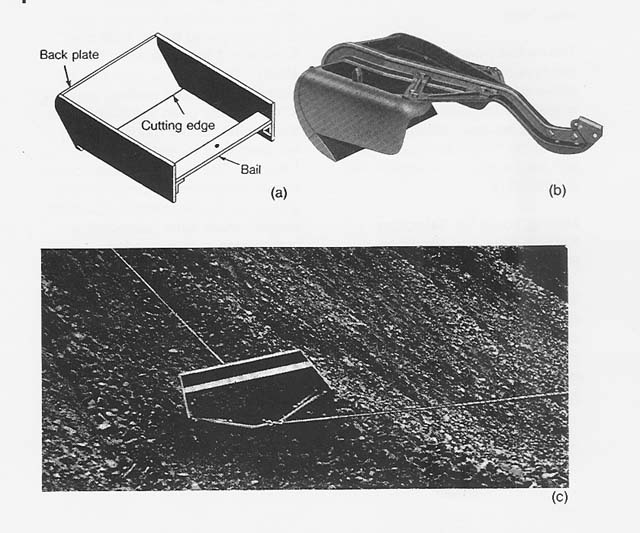

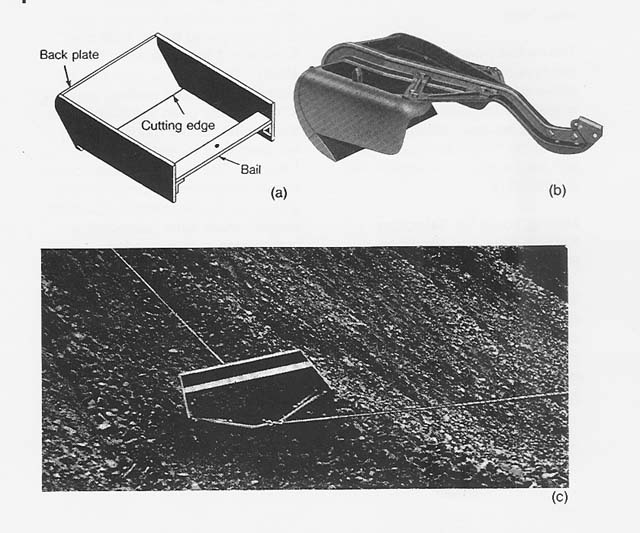

Figure 22

Box-Type Slusher Scrapers

a. Drawing of a Box-Type Scraper

b. Painting of a Full-Box Type Scraper [Shown with a long bail and medium- length

side plates.}

c. Photograph of a Box-Type Scraper [Manufactured in the 1930s of steel plate

construction in use on a stock pile.}

All three taken from Modern Methods for Scraper Mucking and Loading, prepared.

edited. and published by the Ingersoll- Rand Company in 1939.

Two Environmental Factors

In addition to one-sixth gravity, there are two other significant lunar environmental factors worth noting: temperature extremes and electrostatic dust. Temperature extremes are easily answered by shutting down during the lunar night. Heating selected equipment components is feasible, if more expensive. Electrostatic dust is more of a problem. Machinery bearings must be protected, a problem exacerbated by the lunar vacuum, where lubricants may evaporate. One significant feature of the slusher is that it uses very few bearings, even in the mobile version. Lunar bearing designs and lubrication methods must be developed regardless of the mining method used.

Machine Specifications and Fleet Mix

The specifications and fleet mix I present are for the mobile lunar slusher. The reader should note that alternative methods, such as the stationary slusher, were included to illustrate lunar mining design problems and are not specified here. The data given below are for the proposed baseline mobile lunar three-drum system.

The needed raw material for a 100- metric-ton LOX-to-LEO project is 40 000 metric tons. The machine specified below is oversized by a factor of 2.5 or a yearly rate of 100 000 metric tons. This oversizing is to ensure the production is easily accomplished, while demonstrating that a significantly oversized machine is relatively lightweight. Even with this large oversizing, the hourly production is about 25 metric tons per hour. This rate is close to the lowest rate shown on the production table of one manufacturer (Ingersoll- Rand Form 4273A 5-G1 1971).

Specifications:

Yearly production 100 000 metric tons

Span and reach 50 meters

Mined depth 2 meters

Scraper capability 2 cubic meters

Mobile slusher weight 4.5 metric tons

Auxiliary vehicle weight 1.5 metric tons

Ballistic transporter 1 metric ton

Spare parts and tools 2 metric tons

Operation and maintenance 2 people

Foundry (optional) 5 metric tons

Total weight (without foundry): 9 metric tons

Fleet:

1 mobile slusher

1 auxiliary vehicle with small multipurpose crane

1 ballistic transporter