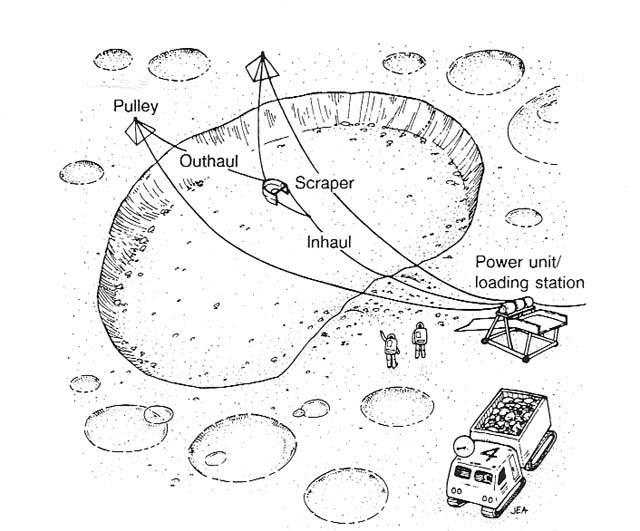

The duty cycle starts with machine setup. The mobile power/loader unit places two pulleys at appropriate locations at the mine site. They could be anchored by large augers in the firm regolith below the loose soil or by other methods. The preferred anchoring method depends on specific site characteristics. After the pulleys are anchored, the power unit similarly anchors itself. The two pulleys and the power unit form a V-shaped mining area. Because machine setup is done only infrequently, is a complex job, and requires firm anchoring, it could be left as a manual operation. For one reason, the anchoring augers might hit buried rocks before they are successfully emplaced. Further study may show that automated or teleoperated setup is also feasible and more desirable.

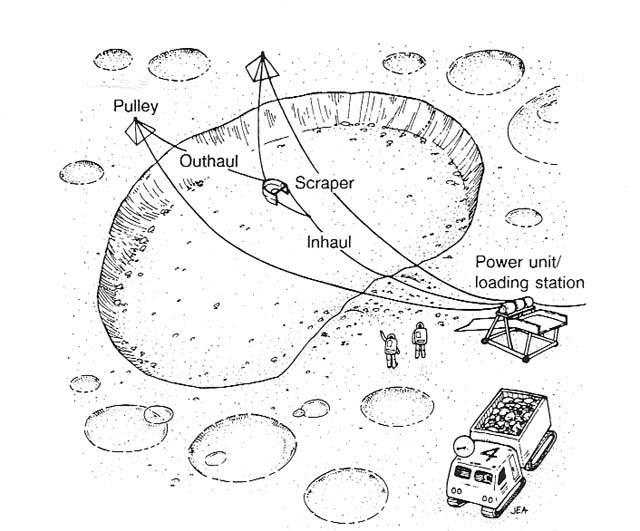

In this short paper, it is impossible to cover adequately all the alternatives and options, even within a well-defined system such as the slusher. However, I will mention one major alternative-a stationary power/loader unit (fig. 20), which is the terrestrial configuration. In this case, the slusher itself would be far simpler, but such a system would require an auxiliary vehicle to transport the slusher from site to site and set it up. A stationary slusher would be less able to remove unexpected obstacles from the pit, as I will discuss. Either way, the excavation duty ,cycle is basically the same.

Figure 20

The Stationary Lunar Slusher

A stationary lunar slusher would have the same operat;onal features as the mobile

slusher. Because it is not self-propelled, it is much simpler and lighter; however,

for the same reason, It requires another vehicle to move iffrom site to site.

From Gertsch 1983.

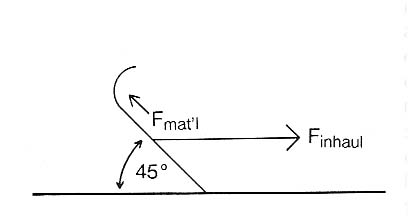

After setup, the excavation duty cycle begins with the scraper (or other tool) at the loading station. The scraper can be moved to any point within the V by a combination of tensions on the two outhaul cables. After reaching the desired position, usually as far into the pit as possible, the scraper is pulled back to the power/loader unit by the inhaul cable. During inhaul, a combination of inhaul force and scraper weight (fig. 21) causes the scraper to fill with loose regolith and carry it back to the power/loader unit. Here the material is pulled up the ramp, discharged from the scraper onto the conveyor, and loaded directly into the mill module.

Figure 21

Forces on a Hoe Scraper

The 45-degree scraping angle is considered optimum. The angle has been determined

by many years of terrestrial experience. It seems most likely that this angle will

be the same for the Moon, but can we be sure? One missing force vector is the weight

of the bucket. For proper operation, the weight of the bucket may need to be augmented

with lunar rocks or other material.

The mill is the electrostatic separator described by Agosto in the section on beneficiation. The separator should be in direct contact with the slusher. This eliminates rehandling of the mined material, resulting in a significant energy saving, since 90 percent of the mined material will be rejected by the separator. The waste from the separator is dumped away from the production area by ballistic transport or another method. Waste transport need only be far enough to keep the separator and slusher from being buried in their own waste.

The box-like scraper will have closed sides to keep the very fine regolith from spilling out, as has been the terrestrial experience.

Because the machine defines its own mining area and machine motions are repetitive, the scraping operation is a reasonable candidate for automation. Feedback control for automatic loading of the scraper will be supplied through sensing the inhaul cable tension. Loading always requires complex motion control, but the problem is more easily resolved with a limited-motion machine such as the slusher than with fully mobile equipment, such as front-end loaders, which have unlimited freedom of motion.

After mining starts, the mobile power unit generally does not move. If an obstacle is uncovered in the pit, the mobile version of the power/loader unit can detach from its anchor and move into the pit. (The anchor is not removed from the soil unless the machine is moving to another site.) To facilitate pit work, the loading ramp is tilted up and a dozer blade extends to its working position. The blade can push boulders out of the pit or mine a small selected area. Because the power/loader unit is lightweight and consequently has poor traction characteristics, it must pull against the outhaul cables when it works a load in the pit. The complexity and uniqueness of this job argue against automating it, but automation is not impossible and teleoperation is a possibility. Both setup and power unit pit work can be done by teleoperation, except for handling severe unforeseen problems that require human intervention.

During normal operation, electric power is supplied to the power/ loader unit by a stationary cable. When the power/loader unit works the pit, it gets its power through a cable reel located at the anchor. One advantage of stationary mining equipment such as the slusher (even the mobile version moves very little during excavation) is simplicity of power supply. Most mobile terrestrial equipment has diesel power, which is rugged, capable, efficient, and, most importantly, onboard. These loaders are very flexible and rugged earth-movers. The lunar alternatives are less satisfactory. Lunar loaders with on board power would probably use electric motors driven by fuel cell or battery technology. Both are expensive options. Versions with external power must be fed electricity through a trailing cable. Terrestrial experience has shown that trailing cables are high maintenance items, but adaptation to the Moon is possible. Another possibility is a' new-technology internal combustion engine, but developing the engine and finding lunar fuel sources are difficult problems.