III. Maximally processed regolith (chemical extraction)

A. Elemental oxygen (product of reduction of lunar material) B. Residues from

oxygen smelting (e.g., from the ilmenite reduction process): rutile (TiO2),

elemental iron, silicate impurities, all intimately mixed C. Products from carbonyl

processing of metal concentrates

D. Products of electrolysis of basalt

E. Products from solar furnace evaporation of silicates

Indigenous conditions assumed are vacuum, sunlight, low gravity on the Moon, and microgravity in near- Earth space. Tools and facilities that should be available include solar furnaces and electrical power at megawatt levels.

From this set of starting materials and facilities, the following classes of products are possible. These are evaluated with respect to properties attainable without further change or purification. Additional equipment needed to produce the products from the starting materials is identified. Also, additives that in small quantities could greatly improve the caliber of these products are identified. Gases, such as oxygen, hydrogen, carbon dioxide, and helium, are useful as generated and do not require further processing.

I. Metal-based

A. Extruded products - beams, rods, wires B. Cast products-beams, rods, containers C. Rolled parts-plates, foils, beams

II. Silicate-based

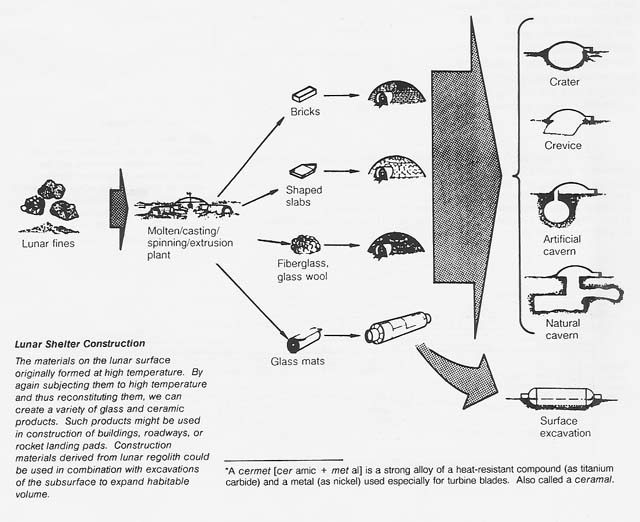

A. Glasses-fibers, rods, light pipes, beams, bricks, coatings, sheets

B. Ceramics, cermets*- containers, bricks, pipes

C. Composites-cement, concrete

D. Sintered silicates-bricks, plates