PART 3-Manufacturing and Fabrication

Sankar Sastri, Michael B. Duke, and Larry A. Haskin

Introduction

The ability to use nonterrestrial materials and energy and to utilize the special properties of space environments will allow the space enterprise to grow at an increased rate. We can envision a self- sufficient space economy, with centers of resource extraction and manufacturing off Earth that provide sustenance to colonies of people. However, in the next 25 years, the infrastructure for using space resources will concentrate on more limited goals, those that will have high leverage on the space economy.

Four general goals for use of non terrestrial resources are

Several possibilities exist to make major augmentations to our space capability

by providing access to materials in space:

This report is deliberately conservative. Previous studies (Criswell 1980) have demonstrated that nearly anything one wants to make in space can be made from the raw materials available on the Moon or on near-Earth asteroids. We have looked instead at what is most easily accomplished in the next 25 years.

The accessibility of material and energy off the Earth and the leverage that these nonterrestrial resources can exert on the space transportation system are important influences on the long-term goal of exploring the solar system. The next 25 years will provide the learning experience necessary to advance that activity more rapidly. The concept of "bootstrapping"- using the production capability to manufacture additional production equipment and expand production more rapidly than if all the production equipment had to be transported from Earth-can be tested and the ability to sustain human settlement beyond Earth can be demonstrated.

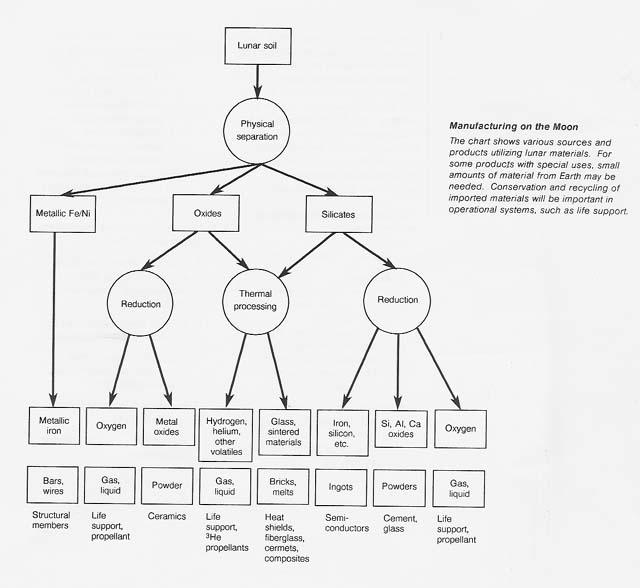

Research on separation of lunar materials and manufacture of useful products from them is in its infancy. Many avenues are left to be investigated. A few possible processes and products are described below.

Products

The least complicated technologies will not necessarily be the most cost-effective ones to manufacture products from nonterrestrial materials. It is nevertheless appealing to imagine that early space manufacture can be done by simple means. It seems that simplicity ought to correlate with economy or at least with probability of early application. Thus, we have chosen to explore the oxygen, metal, and silicate products that might be obtained from simple treatment of well-characterized materials from near-Earth space.

The ground rules of the exercise are these:

The scenario that could result from application of these ground rules to common materials at Apollo sites is limited but far from stifling. To make the problem tractable for this exercise, we have chosen to constrain our list of materials and products even more narrowly than the rules specify. Nevertheless, the examples we treat should be sufficient to illustrate the possibilities and the limitations.

The following are designated as starting materials:

I. Unprocessed lunar regolith

A. Bulk soil

1. Mare-derived; high-iron, high-silicon, low-aluminum. low-calcium

2. Highland-derived; low-iron, high-silicon, high- aluminum, low-calcium

3. Mixed origin; intermediate- composition

B. Rocks

1. Mare basalt [CaAl2Si20g (plagioclase} and (Mg,Fe)SiO3 (low-calci\;Jm pyroxene) ]

2. Highland igneous-rocks

a. Anorthite (primarily plagioclase)

b. Dunite [primarily (Mg,Fe)2SiO4 (olivine)]

c. Troctolite (mixtures of plagioclase and olivine)

d. Norite (mixtures of plagioclase and low- calcium pyroxene)

3. Breccias (physical mixtures of rock, mineral, and glass fragments)

A. Magnetic iron-nickel alloys plus iron-bearing glassy "agglutinates" (separated magnetically)

B. Ilmenite concentrate, FeTiO3 (separated electrostatically)

C. Plagioclase concentrate (separated paramagnetically or electrostatically)

D. Residues from separations of A through C

E. Volatiles (H2, N2, He) driven off thermally