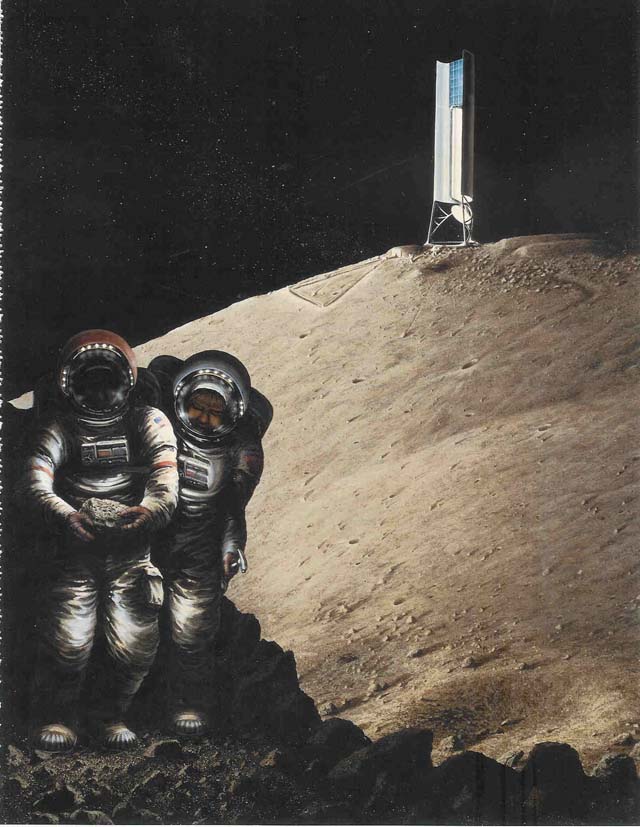

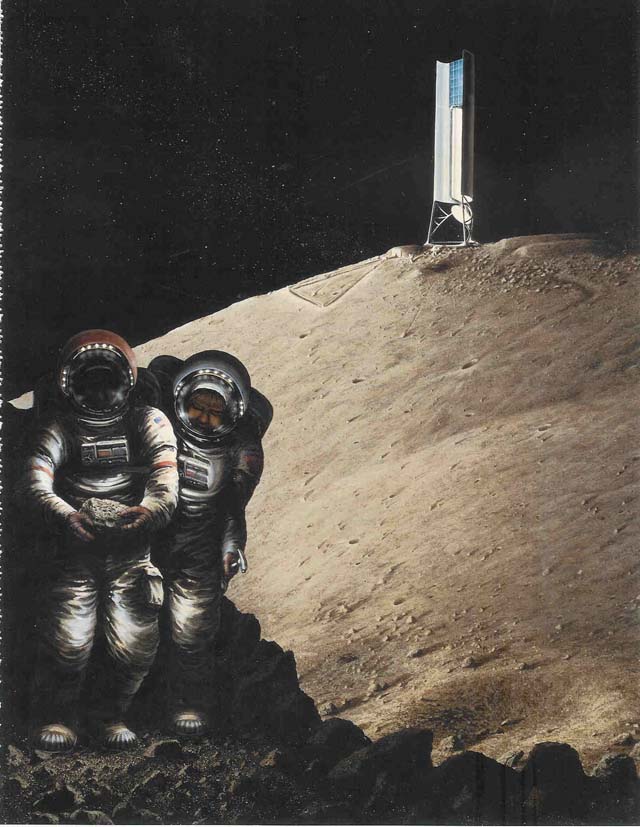

Figure 16

Polar Solar Power System

At a base near a lunar pole,

a solar reflector (the large tower in the background) directs sunlight to a

heat collector, where it heats a working fluid which is used to run a turbine

generator buried beneath the surface. At such a location the solar power tower

can track the Sun simply by rotating around its vertical axis. Power is thus

provided continuously without the 2-week nighttime period which is characteristic

of nonpolar locations. This continuous power would allow continuous mining and

processing operations at the pole.

Note the sharp contrasts between light and

shadow in this picture. The contrasting shadows offer another advantage and

might afford a third. A polar site would have a number of zones that remain

in perpetual shadow, such as inside craters. These zones would be ideal locations

for cryogenic storage depots; the depots would not require active cooling to

maintain oxygen at liquid temperatures. And these permanently shadowed zones

might have served as cold traps for collecting water released from the lunar

interior or from impacts of comets or water-bearing asteroids. Such water, preserved

as ice, might be minable for use in life support or processing into rocket fuel.

The triangle in the background is a mining pit. In the foreground, two scientists

collect rock samples for analysis at the base.

Artist: Maralyn Vicary

The density of sampling should be increased to intervals of 1 to tens of meters, depending on the scale of the anticipated operation. Not only the sample density, but also the sampling technique is inadequate to characterize a site for potential resource extraction.

The sampling program should permit assessment of

1. Mineralogy

2. Grain size distribution

3. Mechanical properties, including shear strength, hardness, compressive strength,

friction angle, and elastic moduli*

4. Depth of regolith

5. Surface topography

6. Geochemical and geophysical information on the site such as resistivity,

gravity, porosity, and the results of seismic and electromagnetic surveys

7. Abrasiveness

Analysis of all these types of data should involve techniques to help quantify the spatial characteristics of the lunar regolith at mining scales. These techniques will be used at the mine site to guide subsequent sampling both before and during production. Modeling should create 3-dimensional representations of the ore body to guide mine layout and design. These models should describe the distribution of material properties, such as ore grade and particle size. Such information is particularly important during the startup and early operations of the processing facility. Variations in the mill feed will be a critical design factor for both the mine and the mill. Blending at the mine will improve mill productivity. Modeling should simulate the entire mine life to permit optimal mining operations that are coordinated with processing ope~ations.

Grain size distribution data will provide guidelines for excavation planning, crusher design, in-pitscreening procedures, and plant feed simulations.

Mechanical property testing will provide parameters to assess mine stability and foundation design under both static and operational dynamic loads. It may be important, for example, to isolate the processing plant from mining and crushing vibrations either through foundation design or through physical site separation.

Measurements of the depth of the loosely compacted lunar regolith or soil will

be used to design the mine, decide on the scope of the operation, and predict

the volume. The depth to which one can mine without high-energy rock breakage

(blasting, etc.) is important

for design and planning. An unexpected change in the depth, geometry, or mineral

character of the regolith could require that the mine and mill be relocated.

And the fewer the equipment relocations, the lower the costs.

Surface topography will determine the general layout of the mine and processing plant. Some topographic features may be advantageous for maximizing gravity feed; others may help minimize excavation.

*By "elastic moduli" I mean to embrace those conventionally measured; namely, Young modulus (E) Shear modulus (G) Bulk modulus (K) Poisson's ratio (v) Further definitions can be found in L. Obert and W. I. Duvall, 1967, Rock Mechanics and the Design of Structures in Rock (New York: John Wiley & Sons), p. 53.

Next