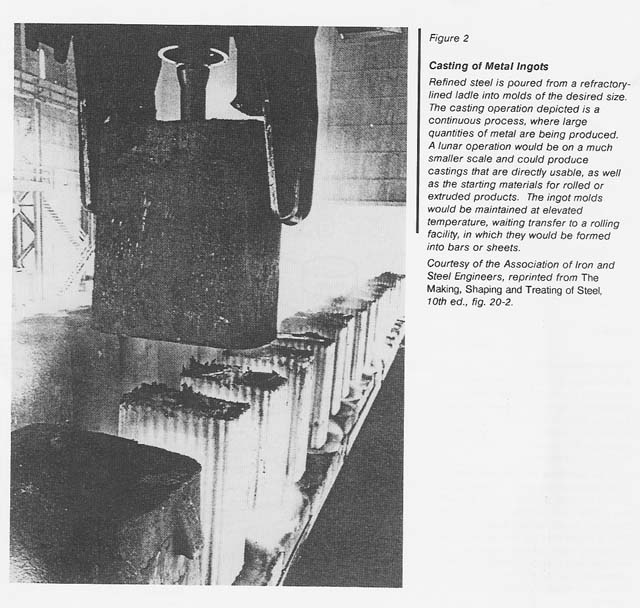

Casting

Casting, one of the oldest processes in the world, involves pouring liquid metal into a mold and allowing it to solidity in that shape (fig. 2). The casting process has to be modified for application in free space because gravity is so limited. Casting at a lunar facility in 1/6 gravity should be straightforward; however, mold construction techniques require study, particularly if indigenous materials are to be used for the molds.

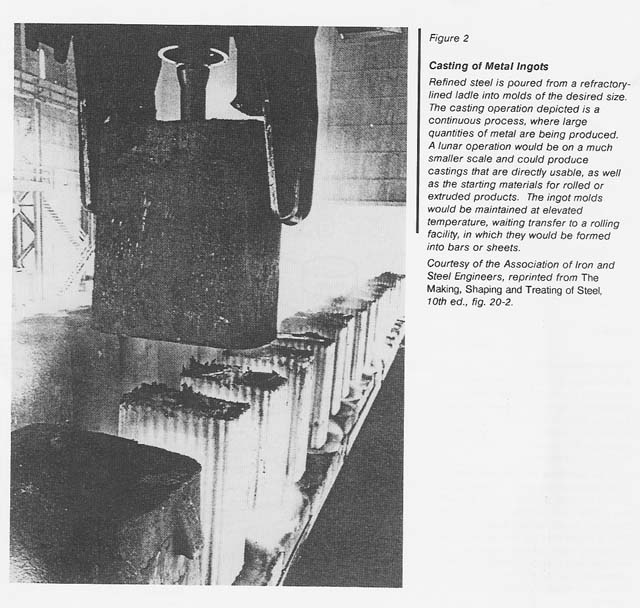

Powder Metallurgy

Powder metallurgy consists of compacting fine metallic powder into a desired shape and sintering the shape (fig. 3). Lubricants may be required to separate pressed parts from the die. The absence of atmosphere in space prevents the formation of oxides or other contaminating layers on the powders and thus may promote the formation of high quality parts.

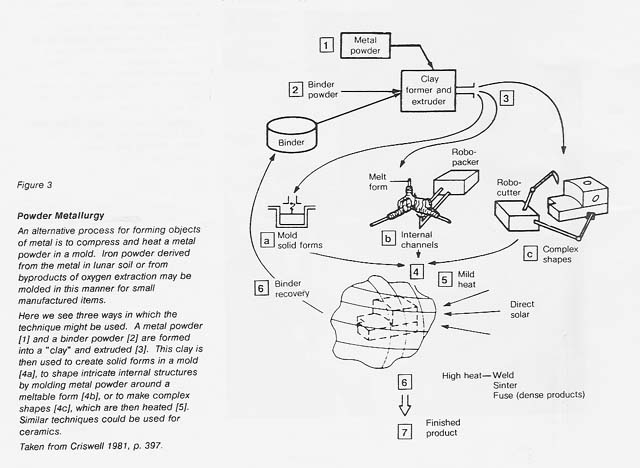

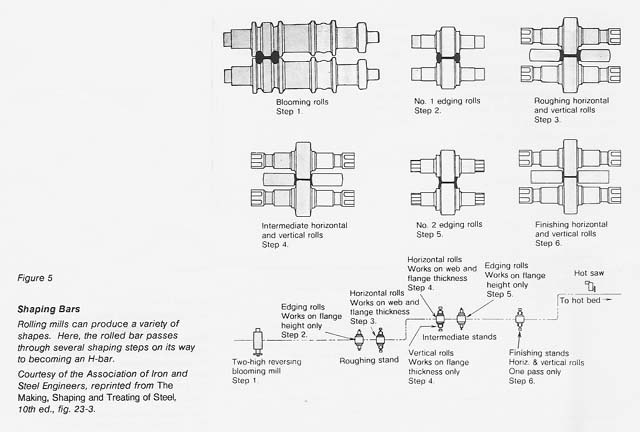

Rolling

Rolling consists of passing a metal between two rolls which revolve in opposite directions, thereby decreasing the cross sectional area and increasing the length of the feedstock (fig. 4). Larger ingots are rolled into blooms having a cross section of more than 6 inches and finally into shapes such as plates, bars, rods, I-beams, and angles (fig. 5). Rolling should be readily adaptable to the space environment, as it does not depend on gravitational forces.

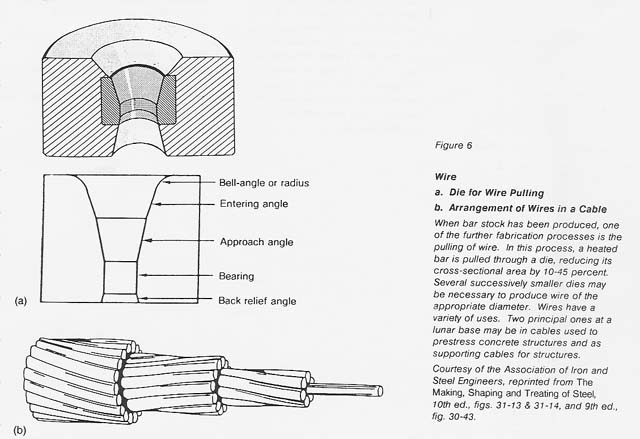

Extrusion

Extrusion is essentially a hot working operation where a metal is extruded through a die or orifice that controls the cross sectional shape (fig. 6). Some common extruded shapes are rods, tubing, and window frames. Extrusion should be easily adapted to space operation.

Cold Welding

Cold welding consists of joining two flat, clean surfaces of a metal by contact and application of pressure. Cold welding works by joining the surfaces at the molecular level. In space and on the Moon, where oxide layer formation is retarded (if not eliminated), cold welding has high potential. In particular, using ceramic rollers to cold roll ultra-pure metals may result in a low-cost way of cold welding. On the other hand, extreme care has to be exercised to keep the surfaces of high-purity metals separate so that undesired cold welding does not take place spontaneously.

Vapor Deposition

Vapor deposition involves allowing vapors of a metal to contact a surface in a closed chamber. On the surface metal layers build up atom by atom. The presence of vacuum makes this process a viable one in a space manufacturing facility. It is particularly suitable for applying thin coatings, such as making highly reflective mirrors.

Although these procedures are plausible for space manufacturing, all are in need of testing and demonstration to ensure that they can be used with typical nonterrestrial metals.