Cement and Concrete

Gene Corley and Larry A. Haskin

The most commonly used construction material on Earth is concrete made with Portland cement. Three quarters or more of the mass of concrete is aggregate, usually sand and gravel. Portland cement, made by sintering limestone, iron ore, and clay, has as its principal constituents anhydrous calcium silicates and aluminates whose typical compositions are 3CaO*' SiO2, 2CaO*SiO2, 3CaO*Al203, and 4CaO*Al203* Fe203. The first three are essential to good concrete strength. In addition, cured concrete contains about 5 percent (by weight) water, a result of the hydration reactions that bind the Portland cement component around the aggregate.

The principal constituent of concrete-aggregate-is abundant on the lunar surface. Lunar mare basalt is similar to terrestrial basalt, which has been used to make concrete with high compressive strength.

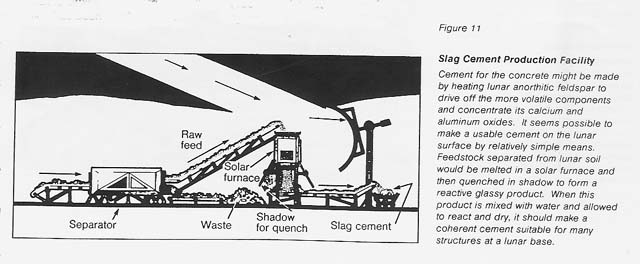

To produce lunar cement, high- temperature processing will be required (see fig. 11). It may be possible to make calcium-rich silicate and aluminate for cement by solar heating of lunar pyroxene and feldspar, or chemical treatment may be required to enrich the calcium and aluminum in lunar soil. The effects of magnesium and ferrous iron present in the starting materials and products would need to be evaluated. So would the problems of grinding to produce cement, mixing, forming in vacuo and low gravity. and minimizing water loss.

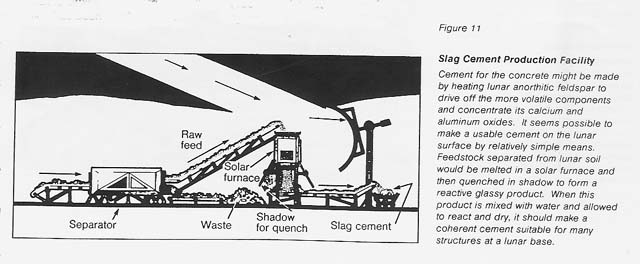

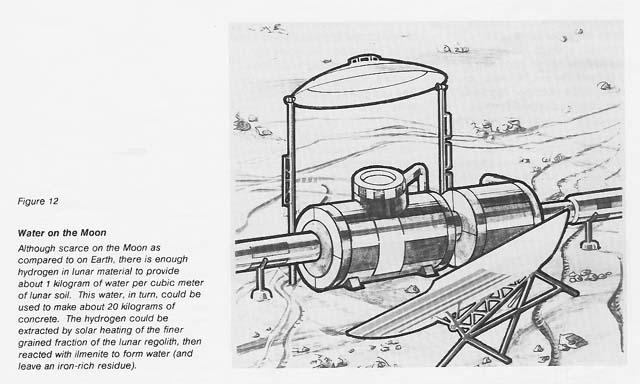

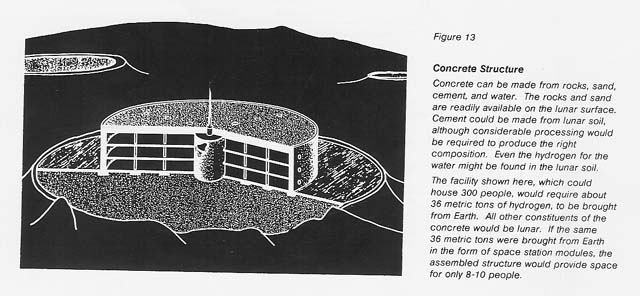

The need for water, a substance not known to exist on the Moon [but oxygen is an element in most lunar compounds and see Carter (1985) for the abundance of hydrogen in the lunar soil], appears to be the most serious deterrent to extensive use of concrete in space. Nevertheless, the convenience of using concrete in space construction has great potential and such use merits close attention. Water may not always be as scarce a commodity as it is now (see fig. 12), and, for some applicatios, concrete might prove cost-effective even if water had to be furnished. This possibility becomes more realistic if lunar oxygen is made available so that only hydrogen has to be imported. The hydrogen content of cured concrete can be as low as 0.5 percent (by weight).

A possible product of interest might be concrete beams reinforced with glass fibers. If imported hydrogen could be used with perfect efficiency, each metric ton could yield 6 kilometers of beams with a cross section of 10 by 10 centimeters. The same amount of hydrogen could yield a wall 10 centimeters thick, 3 meters high, and 24 meters long. Thus, where bulk plus reasonable strength is required or where complex shapes are needed, concrete may be a plausible material to use. See figure 13.

A more complete discussion of concrete's properties and potential uses is found in the second appendix to this part.